What Are Wireless Temperature Monitoring Devices and How Do They Work?

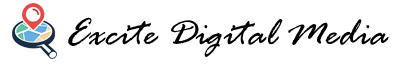

Wireless temperature monitoring devices are like digital guardians in today’s operations. They provide real-time temperature data in various settings without the limitations of physical connections. These smart devices use sensor technology and wireless communication to send accurate temperature readings directly to central monitoring systems.

Core Components of Wireless Temperature Sensors:

1. Temperature Sensing Elements

- Thermocouples: Ideal for high-temperature applications (-200°C to 2000°C)

- RTDs (Resistance Temperature Detectors): Offer superior accuracy (-200°C to 650°C)

- Thermistors: Cost-effective solution for limited temperature ranges (-50°C to 250°C)

2. Communication Technologies

- Radio Frequency (RF): Long-range transmission with minimal power consumption

- Bluetooth: Short-range communication suitable for mobile monitoring

- Wi-Fi: Integration with existing network infrastructure

- Cellular Networks: Remote monitoring capabilities across vast distances

These devices work through a straightforward process: the sensor detects changes in temperature, converts them into electrical signals, and sends the data wirelessly to a central hub or cloud-based platform. This transmitted information allows for real-time monitoring, automatic alerts, and detailed reporting features that are crucial for maintaining operational compliance and product quality.

The use of wireless temperature monitoring drvice systems has transformed industries such as healthcare and food service, providing unmatched control over environments and processes that are sensitive to temperature.

Why Is Choosing the Right Wireless Temperature Monitoring Device Critical for Operations?

Selecting an appropriate wireless temperature monitoring device directly impacts your operational success. The right device ensures precise temperature measurements, safeguards product quality, and maintains regulatory compliance across your facility.

Critical Consequences of Poor Device Selection:

- Inaccurate Readings: Subpar devices can provide false readings, leading to incorrect temperature control and potential product spoilage

- Equipment Damage: Unsuitable sensors might fail to detect temperature anomalies, resulting in costly equipment breakdowns

- Compliance Violations: Non-compliant devices put your operation at risk of failing regulatory audits and facing hefty fines

- Product Waste: Unreliable monitoring can lead to product loss through temperature excursions

- Operational Inefficiencies: Poor device selection often results in increased manual checks and unnecessary labour costs

The stakes are particularly high in temperature-sensitive industries. A pharmaceutical company using inadequate monitoring devices might face batch rejections worth millions of pounds. Food service operations risk foodborne illness outbreaks from improper temperature control. Manufacturing facilities could experience production line shutdowns due to undetected equipment overheating.

Your choice of wireless temperature monitoring device serves as a critical investment in your operation’s success, safety, and compliance standards.

Read more at: Restaurant Temperature Monitoring: Tools for Efficiency and Accuracy

What Factors Should Be Considered When Selecting a Wireless Temperature Monitoring Device?

Selecting the right wireless temperature monitoring device requires careful evaluation of several critical factors. Here’s what you need to assess:

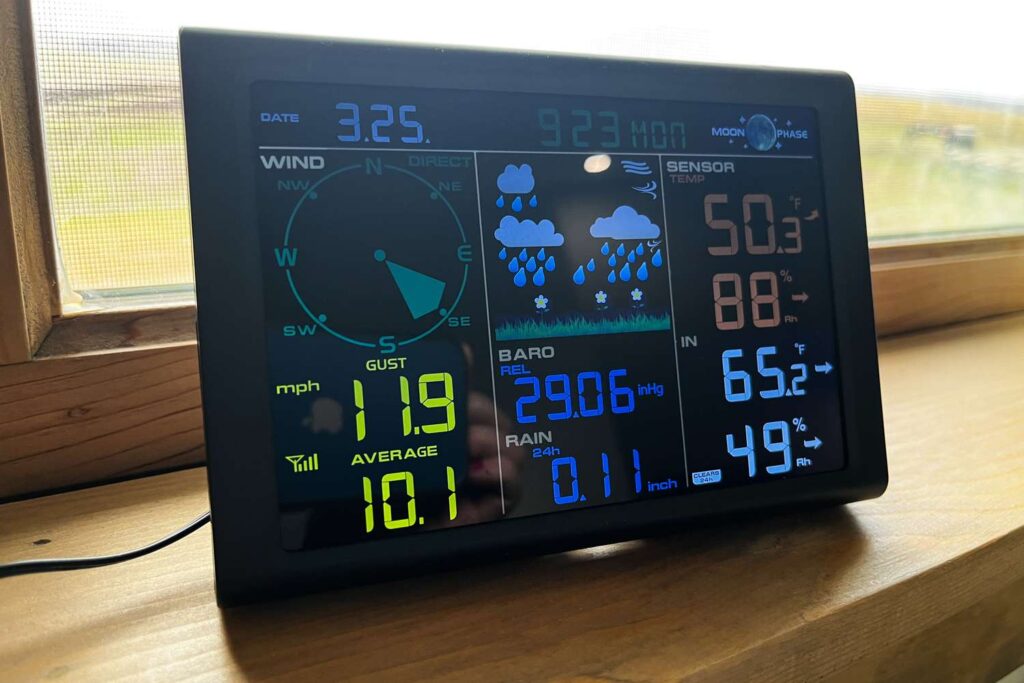

1. Sensor Type and Accuracy

- Active sensors: Provide continuous real-time monitoring with higher power consumption

- Passive sensors: Offer periodic measurements with lower energy requirements

- Accuracy ratings: Look for devices with ±0.5°C precision or better for critical applications

2. Communication Protocol Compatibility

- Wi-Fi enabled devices: Ideal for facilities with existing network infrastructure

- Bluetooth sensors: Suitable for short-range monitoring and mobile applications

- RF protocols: Offer extended range and better penetration through walls

- Cellular connectivity: Perfect for remote locations and wide-area monitoring

3. Power Management Features

- Battery life expectations: Standard batteries (6-12 months) vs extended life options (2-5 years)

- Energy harvesting capabilities: Solar, thermal, or vibration-powered options

- Backup power systems: Essential for critical monitoring applications

- Low-battery alerts: Automated notifications for timely maintenance

4. Environmental Considerations

- Operating temperature range: -30°C to +70°C for industrial applications

- IP ratings: IP65 or higher for water and dust resistance

- Humidity tolerance: 0-100% RH for varied environments

- Chemical resistance: Essential in manufacturing or laboratory settings

5. Data Storage and Transmission

- Local storage capacity: Buffer size for offline operations

- Transmission frequency: Adjustable intervals to balance power usage

- Data encryption: Security protocols for sensitive information

- Cloud integration capabilities: API compatibility with existing systems

These factors directly impact the effectiveness of your temperature monitoring system. Your specific operational requirements should guide the selection process, ensuring the chosen device aligns with your monitoring needs and environmental conditions. Learn more about effectiveness on https://www.tandfonline.com/doi/full/10.1080/10872981.2020.1757883

How Do Different Industries Benefit from Using Wireless Temperature Monitoring Devices?

Wireless temperature monitoring devices have transformed operations in various industries, each with its own specific needs and uses. Let’s take a closer look at how different sectors utilise this technology to improve efficiency and uphold quality standards.

Food and Beverage Industry

- Ensures food safety through continuous cold chain monitoring

- Tracks temperature in storage units, display cases, and preparation areas

- Prevents food spoilage and maintains compliance with health regulations

- Reduces manual temperature checks, saving staff time

- Documents temperature data for audit trails and HACCP compliance

Pharmaceutical Sector

- Maintains strict temperature control for sensitive medications

- Monitors laboratory conditions for research integrity

- Ensures compliance with Good Manufacturing Practice (GMP)

- Protects vaccine efficacy during storage and transport

- Provides real-time alerts for temperature deviations

Logistics and Transportation

- Tracks temperature-sensitive cargo throughout shipping routes

- Validates cold chain integrity for perishable goods

- Reduces product loss during transit

- Creates detailed temperature mapping for quality assurance

- Enables quick response to temperature fluctuations

Manufacturing Operations

- Controls production environment conditions

- Monitors equipment temperature for preventive maintenance

- Ensures product quality through consistent temperature control

- Tracks heating and cooling processes

- Reduces energy consumption through optimised temperature management

Healthcare Facilities

- Safeguards medical supplies and specimens

- Monitors storage conditions for blood banks

- Maintains proper temperature in patient care areas

- Ensures compliance with healthcare regulations

- Protects temperature-sensitive medical equipment

Each industry uses wireless temperature monitoring to tackle specific problems while enhancing operational efficiency and preserving product integrity. The ability to gather and analyse temperature data in real-time empowers businesses to make informed decisions and uphold quality standards throughout their operations. Click here to find more about integrity.

What Are Some Common Challenges Faced During Implementation Of Wireless Temperature Monitoring Systems?

Implementing wireless temperature monitoring systems presents several technical and operational challenges that organisations need to address for successful deployment.

Signal Interference and Range Limitations

- Physical barriers like metal structures and thick walls can disrupt wireless signals

- Multiple electronic devices operating in the same frequency range create interference

- Distance between sensors and receivers affects data transmission reliability

Power Management Issues

- Battery life limitations in remote sensors

- Unexpected power failures leading to data gaps

- Energy consumption variations in different environmental conditions

Integration Complexities

- Compatibility issues with existing systems

- Data format inconsistencies across platforms

- Network security protocols affecting system performance

Staff Training and Adoption

- Resistance to new technology implementation

- Learning curve for system operation

- Time investment required for proper training

Practical Solutions

- Conduct thorough site surveys to identify optimal sensor placement

- Install signal repeaters in strategic locations

- Implement redundant power sources and backup systems

- Use professional installation services for complex deployments

- Create detailed training programmes with hands-on practice sessions

- Establish clear standard operating procedures

- Regular system maintenance and calibration schedules

Technical Configuration

- Select appropriate transmission frequencies based on environment

- Configure optimal sampling rates to balance accuracy and battery life

- Implement robust data encryption and security measures

- Set up automated alerts for system malfunctions

These challenges require careful planning and systematic approach to ensure successful implementation of wireless temperature monitoring systems.

How Can Organizations Ensure Long-Term Reliability And Accuracy Of Their Chosen Wireless Temperature Monitoring Devices?

Regular calibration is essential for maintaining reliable wireless temperature monitoring systems. A structured maintenance schedule helps identify potential issues before they disrupt operations:

Essential Calibration Practices:

- Quarterly sensor verification against certified reference devices

- Annual comprehensive calibration by certified technicians

- Documentation of all calibration activities and results

- Immediate recalibration after any significant environmental changes

Industry-Specific Requirements:

- Food service: Compliance with HACCP guidelines requiring ±0.5°C accuracy

- Pharmaceutical: GDP and GMP standards mandate calibration traceable to national standards

- Healthcare: Joint Commission standards for temperature monitoring equipment

Preventive Maintenance Protocol:

- Weekly physical inspection of sensors

- Monthly battery level checks

- Regular cleaning of sensor components

- Software updates and firmware maintenance

Organisations should implement a robust validation system that includes:

- Performance qualification (PQ) tests

- Installation qualification (IQ) documentation

- Operational qualification (OQ) procedures

- Regular system audits

Best Practices for Accuracy:

- Use of calibration certificates

- Implementation of drift monitoring

- Establishment of alert thresholds

- Creation of detailed maintenance logs

These practices align with Squizify’s automated record-keeping capabilities, ensuring consistent compliance and operational excellence across different regulatory environments.

What Role Does Data Management Play In Maximizing The Benefits Of Wireless Temperature Monitoring Systems?

Data management is crucial for making wireless temperature monitoring systems work effectively. It takes the basic temperature readings and turns them into useful information. With a strong data management plan, you can fully utilise your monitoring devices in the following ways:

1. Advanced Analytics Capabilities

- Predictive maintenance algorithms identify potential equipment failures before they occur

- Pattern recognition detects temperature anomalies across multiple monitoring points

- Historical trend analysis reveals seasonal variations and long-term temperature patterns

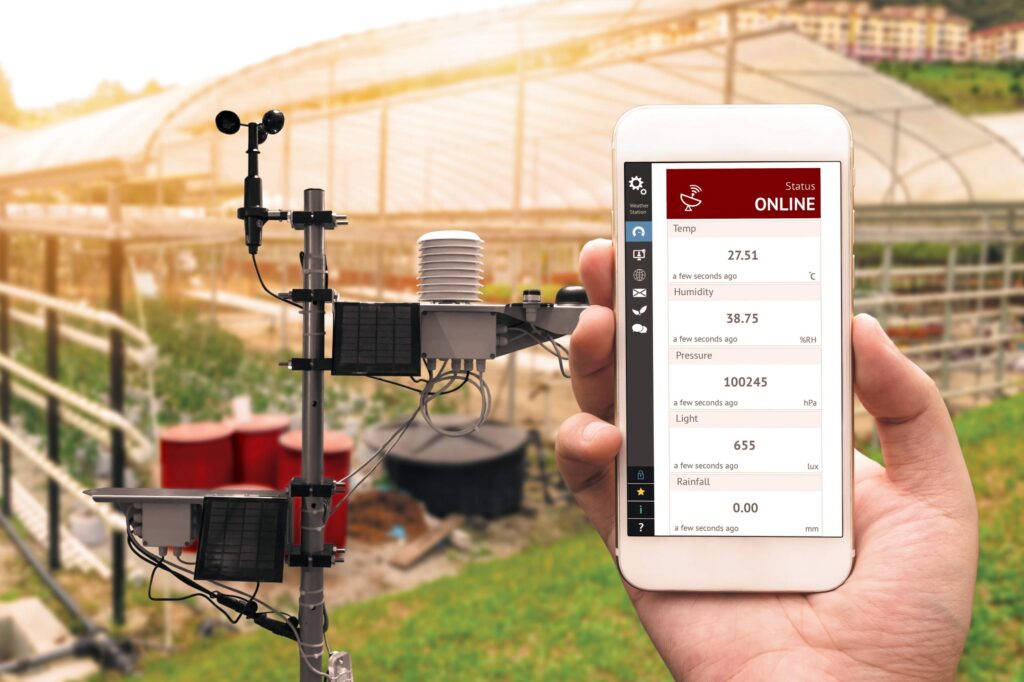

2. Real-Time Decision Making

- Automated alerts trigger immediate responses to temperature deviations

- Dashboard visualisations display critical temperature data at a glance

- Mobile accessibility enables remote monitoring and quick interventions

3. Integration Benefits

- Seamless connection with existing business systems

- Automated reporting for compliance requirements

- Data-driven inventory management optimisation

4. Performance Optimisation

- Energy consumption analysis for cost reduction

- Equipment efficiency tracking

- Resource allocation based on usage patterns

Solutions like Squizify enhance these capabilities by providing:

- Secure cloud storage for temperature data

- Custom reporting tools

- API integration options

- Automated record-keeping

- 24/7 data accessibility

A well-organised data management system changes temperature monitoring from just a task for meeting regulations into a powerful tool for running operations. The information gathered from this system leads to better processes, less waste, and more informed decisions throughout your organisation.

Conclusion

Choosing the right wireless temperature monitoring device is crucial for your operational success. A well-chosen system provides accurate measurements, meets compliance standards, and safeguards your products’ integrity.

Your decision affects:

- Data accuracy and reliability

- Regulatory compliance

- Operational efficiency

- Cost management

- Long-term sustainability

Take time to assess your specific needs:

- Required temperature ranges

- Environmental conditions

- Communication protocols

- Power requirements

- Data management capabilities

Carefully considering these factors helps you find a solution that matches your operational goals. Think about scheduling a personalised demo with temperature monitoring experts who can assist you in the selection process. Your investment in the right wireless temperature monitoring system will bring benefits such as better operational control, lower risks, and improved decision-making abilities.

Ready to change the way you monitor temperature? Book a demo with our team to learn how Squizify’s solutions can meet your specific needs.